🌍 Making flying sustainable #16

The challenge of electrifying planes and how to make sustainable fuels

Hi there 🤗

Welcome to another edition of the ‘tings newsletter 🌍

👀 This edition at a glance

Flying is awesome, it has brought our world together!

Electrifying airplanes is difficult - a large plane takes of with the energy of 17,600 Teslas ⚡️

Synthetic fuels have had a difficult history but have the potential to significantly reduce aviation emissions without needing new planes 🛩

Sustainable aviation fuels can be made in multiple ways

Phycobloom are engineering algae to produce cheap biofuels

INERATEC turn water and captured CO2 into fuels

Metafuels can produce fuels from biomass like wood waste

Sustainable aviation fuels will impact more than just aviation

🛫 Flying is awesome

The sensation of the g-forces pushing you into your seat during takeoff, the views you get when flying over the alps, and the magic of going from rainy Berlin to a destination filled with sunshine is amazing. If you can’t tell, I really like flying. This is definitely due to the fact that my dad is a pilot and that I’ve got to experience takeoffs and landings directly from the cockpit, but I think even people who didn’t grow up in a pilot family have greatly benefited from flying.

Flying has shrunk our world, it has connected people, shared cultures and ideas. It is a truly transformational invention that allowed humanity as a whole to progress and the connecting power of flying probably enabled countless more transformational inventions to come to life. For all the benefits of flying we cannot ignore the environmental impact that comes as a result of it. If we look at annual CO2 emissions per country aviation would come in as the 5th largest country behind Russia and just in front of Japan.

Note: flying emits more than just CO2 but for that topic I suggest reading the post of Survivaltech.club another great substack newsletter!

🔋 Electrifying airplanes is difficult

Electrifying airplanes would be an ideal and low-carbon solution but unlike cars, that can easily be electrified, airplanes don’t drive on solid ground that supports the added weight of batteries. To pack an airplane with enough energy to takeoff, the batteries would be so heavy that it wouldn’t be able to. The Airbus a330-300, one of the most common long-haul planes and the one my dad flies, consumes 5,700kg of fuel per hour of cruising, which equates to around 68,400 kWh. The Tesla Model 3 battery has a useable capacity of 75 kWh and weighs 480kg. This means that for 1 hour of flight time you would need the batteries from 912 Tesla Model 3s adding 437 tonnes in weight, which is almost double the maximum takeoff weight of the a330-300, without the weight of the airplane included. For a full flight you would need the energy of 17,600 tesla model 3 batteries, which weigh as much as 56 adult blue whales (8,448 tonnes). See the problem? Kerosene has an energy density of almost 12,000 Wh/kg which is quite a lot higher than the 156 Wh/kg of a Tesla Model 3 battery.

Electrifying airplanes, or at least long-haul airplanes, will need as big of a breakthrough as the invention of flying. In 1903, the New York Times predicted, with the help of mathematicians and scientists, that airplanes would take 10 million years to develop... the Wright Brothers achieved manned flight nine weeks later 😂

⛽️ Sustainable aviation fuels promise carbon-neutral flying

Something that will happen sooner, with a little less of a leap, is the development of sustainable aviation fuel (SAF), fuels made from sustainable feedstocks instead of using fossil fuels. SAFs come in two main forms: biofuels and eFuels. Biofuels are made using biomass (plant-based materials) and eFuels are made through the conversion of CO2 and hydrogen with renewable electricity. The sustainability of SAFs can vary depending on production method, which according to the EU range between a 70% - 90% reduction in greenhouse gas emissions compared to existing jet fuels. In theory, SAFs are carbon-neutral as the production removes as much CO2 from the atmosphere as is later released when the fuel is burned. One of the biggest benefits of SAFs, besides reducing emissions, is that they can be used as drop-in-fuels, meaning that they work in existing planes, so we can avoid having to re-tool an entire industry.

SAFs have had a bit of a difficult history with a fair bit of criticism. There was a biofuel bubble between 2005-2012 where numerous startups that raised a lot of money failed or pivoted away, biofuels have been criticized for using food sources as feedstocks, and that eFuels are way too expensive. I think the only one that is warranted is that biofuels should not be made with food sources, but criticism that the technologies for eFuels or other biofuels are too expensive and should be avoided is about as good of an argument as the one from the New York Times about flying. We don’t have time to avoid something difficult... climate change is not waiting for anyone! For the price of SAFs to come closer to that of their fossil-based counterparts requires investment, and a lot of it.

🌱 Phycobloom - engineering algae for carbon-neutral biofuel

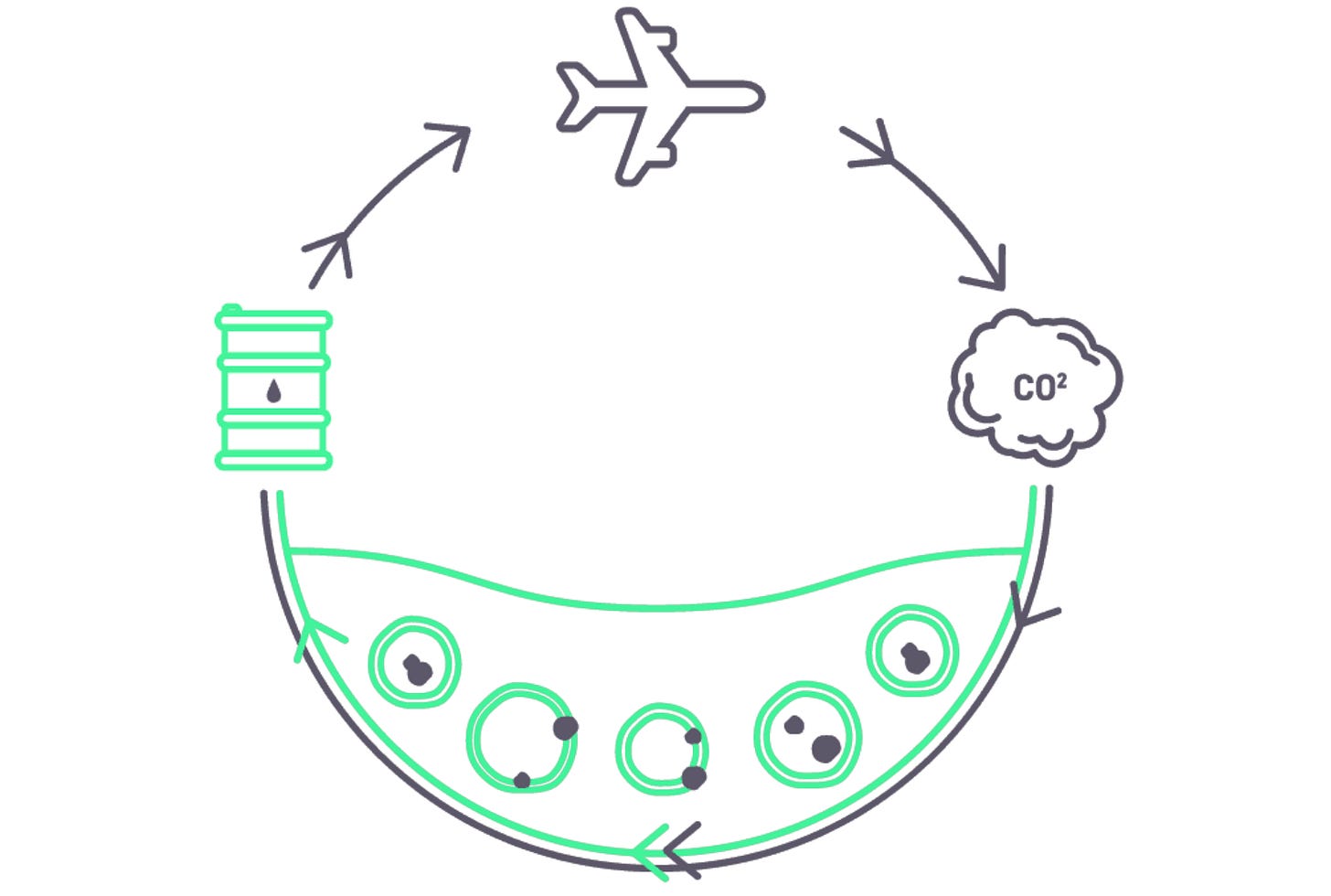

One virtually unlimited source of biomass as a feedstock for biofuel is algae. As we discovered in the previous edition of ‘tings, algae grows much faster and captures more carbon than land-based plants, which is what makes them an ideal candidate for the production of fuels. However, existing methods would only be able produce about 3-5 percent of jet-fuel needs by 2050 according a professor from Munich’s Technical University. Traditional methods of extracting oil from algae either involve mechanically pressing or dissolving them in a solvent, which ultimately kills the algae. Phycobloom, a London-based startup is looking to change this with their new even more sustainable method of extracting oil from algae. Instead of pressing or dissolving the algae, they are genetically engineering strains to continuously release oils into their surroundings, eliminating the need to regrow algae for each batch. This way the algae produces more oil at a lower cost compared to existing methods.

Image: The algae fuel cycle. Source: Phycobloom

💨 INERATEC - turning CO2 and water into fuel

The other virtually unlimited production method for SAFs is by using renewable energy, CO2, and water to produce carbon-neutral fuels in a process aptly named power-to-liquid. The key here is that instead of using algae to capture CO2 from our atmosphere, waste CO2 is captured from intensive industrial processes like cement or steel production, or even captured directly from the surrounding air. The captured CO2 is then mixed with hydrogen, that was separated from water through electrolysis, in a reactor to produce syngas. The syngas is further refined in a fischer-tropsch reactor to produce high quality chemicals that can be refined into synthetic fuels such as gasoline, diesel, or kerosene.

The German startup INERATEC is trying to commercialize and scale this technology through their modular chemical plants. Unlike, algae that depend on the right conditions to photosynthesize, INERATEC’s plants, that come in 30ft shipping containers, can easily be installed across the world wherever there is renewable energy and CO2. They started production of the world’s largest power-to-liquid plant in Karlsruhe, Germany in April that will produce 3,500t of synthetic fuel per year by 2023.

Image: INERATECs modular chemical plant. Source INTERATEC

🪵 Metafuels - making sustainable aviation fuel from wood waste

Metafuels a Swiss startup is taking a similar approach to INERATEC in that they are developing a process to create sustainable aviation fuels from water and CO2 using renewable energy sources. However, rather than using the fischer-tropsch method they rely on methanol synthesis where the intermediary product of methanol is produced on the pathway to creating sustainable aviation fuels. The interesting thing about the process that Metafuels dubbed aerobrew™ is that the methanol can also be derived from renewable cellulosic biomass like wood for example. This way they bridge the gap between biofuels and efuels to create a more flexible production process.

Note: I am not a scientist or expert in this field so I will not even attempt to explain the difference between fischer-tropsch and methanol synthesis, maybe there’s someone reading this who can? (please let me know 😇)

🛫 SAFs will impact more than just aviation

In the end, SAFs will not come from one source, the global demand for sustainable fuels is far too large for that, so we will likely see SAFs made from biomass like algae or wood waste as well as efuels made from nothing but water and CO2. The true magic of drop-in SAFs is that existing planes will be able to use them with no modification and that other hard to electrify transportation sectors like shipping and trucking will benefit from the technology too.

Hope you enjoyed this one! (let me know below ⬇️)

Until next time, much love,

Pascal 💚

🌍 How did you enjoy 'tings #16?

Love | Like | Ok | Meh | Bad (Vote by clicking on the word)

Follow me on LinkedIn, send me links, questions, and feedback. Just hit reply!

☕️ Support ‘tings by buying me a coffee

I spend more than 10 hours per ‘tings edition, so if you want to help fuel the process feel free to buy me a coffee here 🤗